The hydraulic filter protects your hydraulic system components from damage caused by particle-induced oil or other hydraulic fluid contamination in use.

Get a Quote

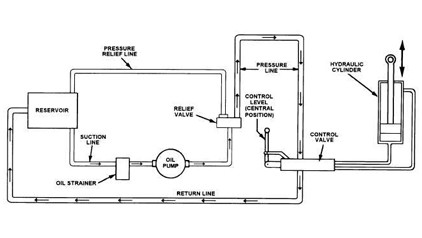

Hydraulic oil filtration is the only solution to eliminate contaminants in the fluid used. Particle filtration using different types of filters will remove contaminant particles in hydraulic oil, such as metals, fibers, silica, elastomers, and rust. The hydraulic filter continuously removes contaminants from the hydraulic oil in the hydraulic system. This process will purify the hydraulic oil and protect the system from damage caused by particle content. Hydraulic filters are loed in different parts of the hydraulic system to prevent pollutant particles from entering the system.

Free Quote

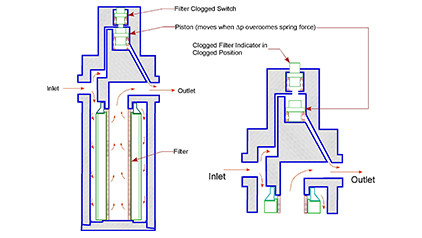

Most hydraulic filters are cylindrical devices with openings for fluid input and output on opposite sides of the filter. The fluid is usually directed through channels in the filter housing and through the filter media. The media then collects contaminants, and the cleaned fluid passes through the central channel between the filter media to the output end. Contaminants are still trapped in the filter medium; when the filter is full, the switch usually triggers an LED or other visual indior to notify that the filter needs to be replaced.

Free Quote

Hydraulic oil is the most important part of every hydraulic system. In a hydraulic system, no system can work without proper volume of hydraulic oil. The risk of hydraulic oil contamination increases with the increase in hydraulic system usage. Leakage, rust, aeration, cavitation, damage to seals, etc. will cause the hydraulic oil to be contaminated. The problems caused by this contaminated hydraulic fluid are classified as degradation, transient, and astrophic failure.

Free QuoteThe importance of hydraulic oil filtration:

For a long time, the importance of hydraulic oil filter or hydraulic oil filter has not been paid attention to. People think that if there is no problem with hydraulic equipment, there is no need to check hydraulic oil. The problems are mainly in these aspects:

1. Inattention and misunderstanding of management and maintenance technicians;

2. It is considered that the newly purchased hydraulic oil can be directly added to the oil tank without filtering;

3. The cleanliness of hydraulic oil is not connected with the service life of hydraulic components and seals and the failure of the hydraulic system.

In fact, the cleanliness of hydraulic oil directly affects the normal operation of hydraulic equipment. Relevant studies have shown that 80% to 90% of press failures are caused by the pollution of the hydraulic system. main problem:

1) When the hydraulic oil is severely oxidized and dirty, it will affect the action of the hydraulic valve, and the valve will be stuck and the valve core will wear quickly;

2) When the hydraulic oil is oxidized, emulsified and particle pollution occurs, the oil pump will malfunction due to cavitation, corrosion of the copper parts of the oil pump, and insufficient lubrication of the moving parts of the oil pump, and even the pump will burn;

3) When the hydraulic oil is dirty, the life of the seals and guides will be greatly shortened;

Causes of hydraulic oil pollution:

1) Friction of moving parts, impact of high-pressure oil flow;

2) Wear of seals and guides;

3) The waxy substances produced by the oxidation of hydraulic oil and other qualitative changes.

The correct way to maintain the cleanliness of hydraulic oil:

1) The hydraulic system must be equipped with an independent high-precision circulating filter system and a high-precision oil return filter;

2) When changing the oil, the new oil must be filtered and then added to the oil tank, and care must be taken to avoid secondary pollution;

3) Strictly control the oil temperature, the normal oil temperature should be controlled at 40~45℃;

4) Regularly check the cleanliness and oil quality of hydraulic oil;

5) Replace the filter element in time every two to three months when the filter alarms.

The choice of filter and filter element precision should consider the balance of economy and technology. The use of our hydraulic oil filtration products can solve this contradiction very well. If necessary, improve the existing filter system and adopt a higher-precision filter element to reduce the failure of the press due to the unclean hydraulic oil.

How to replace and clean the hydraulic oil filter

Hydraulic oil filters are generally used in hydraulic stations and hydraulic systems. After a period of use, because the hydraulic oil filters are blocked by stains inside the hydraulic oil, they should be cleaned regularly to achieve a certain filtering effect.

If the hydraulic oil filter material is made of metal mesh or copper mesh, it can be soaked in kerosene for a period of time, and then the clogged dirt can be cleaned by the wind.

If the hydraulic oil filter material is glass fiber or filter paper, it cannot be cleaned and the cleaning will not be effective. In this case, a new hydraulic oil filter needs to be replaced.

How to replace the hydraulic oil filter?

If it is a suction filter, there are a built-in filter and an external filter. The built-in filter must be pumped to replace the filter below; the bolts outside the filter are directly removed from the outside, and the filter is taken out. At the same time, the oil is locked by the check valve and will not flow out. This is very convenient.

If it is a return filter, it can be replaced directly.

Kainuosen Filter is a professional filter manufacturer. We produce and replace a variety of brand-name filter elements, such as PALL, HYDAC, ARGO, LEEMIN, PARKER, etc. We have been specializing in this field for many years, with oil filter series, air filter series, water filter series and other high-quality and low-cost products.

Our services cover all industries and reach all parts of the world.We can make all kinds of products for you according to your design.